Pick-Radar®

Kontrolle der Entnahmen mit einem modernen Laser

Der rotierende Laser (Class1) erkennt den Zugriff des Mitarbeiters auf die einzelnen Lagerfächer und löst bei Fehlern einen Alarm aus.

Das Prinzip der innovativen Pick-Radar Lösung

Eigentlich ist Pick-Radar® alleine kein Kommissioniersystem. Es geht hier um eine Kontrolle der Zugriffe auf die Lagerfächer. Ein Laserkopf vom Pick-Radar® (keine Radarwelle) rotiert 50-mal pro Sekunde und misst die Entfernung und den Winkel zu den Gegenständen (z.B. einer Hand). Die Messdaten werden direkt an den LUCA-Server oder LUCA-Device-Gateway gesendet. Die Arbeitsfläche wird durch eine Konfiguration bei der Inbetriebnahme definiert. Auf der Arbeitsfläche sind die einzelnen Funktionsflächen konfiguriert. Auf dem LUCA-Server (Kommissionierung oder Sortierung) werden die entsprechenden Funktionsflächen aktiviert und die Rückmeldungen in Echtzeit ausgewertet. Erfolgt der Zugriff in eine der aktiven Funktionsflächen, wird der Prozess benachrichtigt und eine Reaktion ausgelöst. Es werden keine Daten der Mitarbeiter erfasst oder protokolliert.

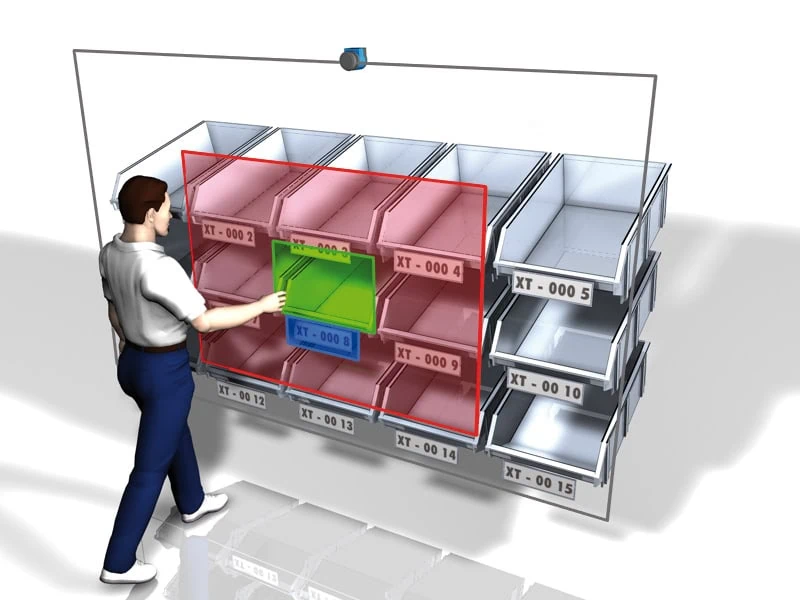

Die virtuellen Funktionsflächen sind frei konfigurierbar

In der Zeichnung oben sind die virtuellen Funktionsflächen farbig markiert.

Folgende Funktionsflächen werden frei konfiguriert und durch das System entsprechend aktiviert (Farben aus der Grafik):

- Zugriff (GRÜN)

- Verboten (ROT)

- Quittierung (BLAU)

- Arbeitsfläche (der Rahmen)

Die maximale Größe der Arbeitsfläche beträgt pro Gerät ca. 20 Meter. Es können mehrere Laser in dem LUCA-System integriert werden.

Wo wird das Pick-Radar eingesetzt?

Das Pick-Radar® wird meistens als Überwachungssystem für die Zugriffskontrolle bei der Kommissionierung aus Fachbodenregalen, Paletten und bei der Sortierung eingesetzt. Das System arbeitet als Ergänzung mit anderen Kommissioniersystemen, wie Pick-by-Point®, Pick-by-Light oder Pick-by-Voice, etc. Bei Automotiv (immer 1 Stück) wird die automatische Quittierung der Entnahme direkt mit dem korrekten Zugriff ausgelöst. Der Warenausgang ist auch ein klassisches Beispiel für den Einsatz des Pick-Radars.

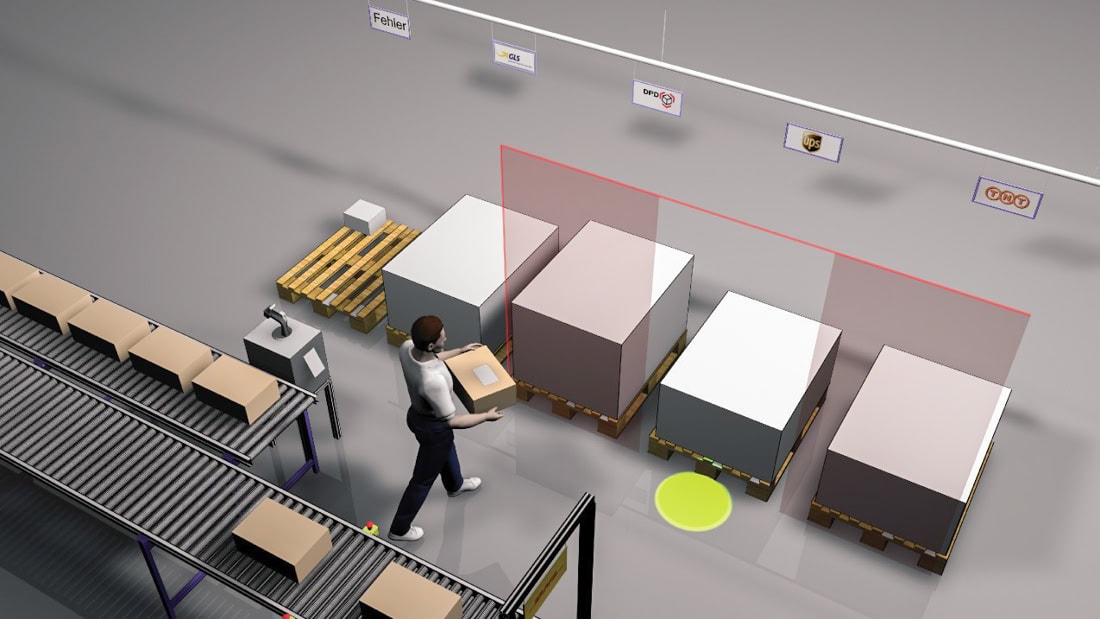

Beispiel der Ablagekontrolle von Paketen in einem Warenausgang

In diesem Beispiel überwacht das Pick-Radar die Ablage des Versandkartons auf der korrekten Palette. Die Vorgabe der Zielpalette wird hier mit einem Pick-by-Point-System (der gelbe Lichtpunkt) realisiert. Ist der Karton korrekt abgelegt, übernimmt das System die automatische Quittierung. Greift der Mitarbeiter in ein falsches Fach, wird der Lichtpunkt des Pick-by-Point-Systems rot und groß angesteuert. Optional können auch akustische Warnsignale verwendet werden. Durch Einsatz des Pick-Radars® können die Sortierungsfehler sehr stark reduziert werden.