Pick-Radar®

Checking the removals with a modern laser

The rotating laser (Class1) detects the employee's access to the individual storage compartments and triggers an alarm in the event of errors.

The principle of the innovative Pick-Radar solution

Pick-Radar® alone is not actually a picking system. It is about controlling access to the storage compartments. A Pick-Radar® laser head (not a radar wave) rotates 50 times per second and measures the distance and angle to the objects (e.g. a hand). The measurement data is sent directly to the LUCA-Server or LUCA device gateway. The work surface is defined by a configuration during commissioning. The individual functional surfaces are configured on the work surface. On the LUCA-Server (picking or sorting), the corresponding function areas are activated and the feedback is evaluated in real time. If access is made to one of the active functional areas, the process is notified and a reaction is triggered. No employee data is recorded or logged.

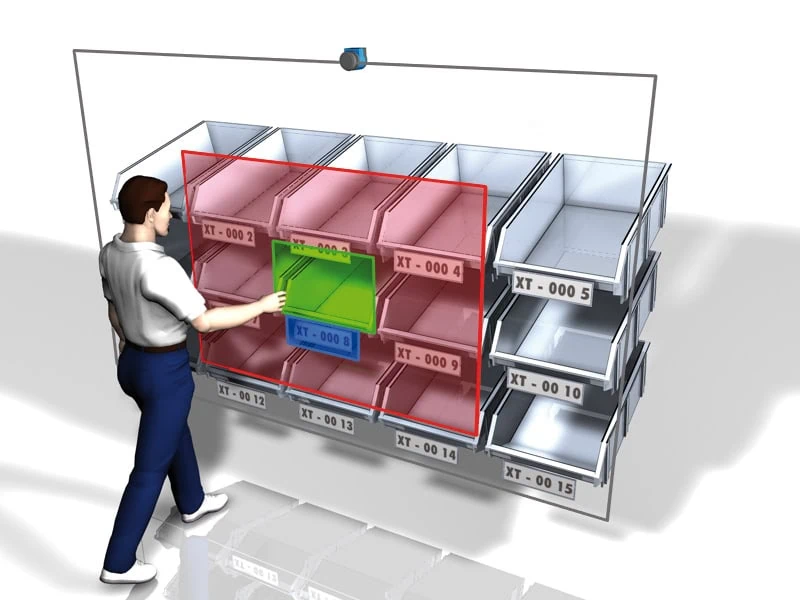

The virtual function areas are freely configurable

The virtual function areas are highlighted in color in the drawing above.

The following functional areas are freely configured and activated accordingly by the system (colors from the graphic):

- Access (GREEN)

- Forbidden (RED)

- Acknowledgement (BLUE)

- Work surface (the frame)

The maximum size of the working area per device is approx. 20 meters. Several lasers can be integrated into the LUCA system.

Where is the Pick-Radar used?

The Pick-Radar® is mostly used as a monitoring system for access control when picking from shelving racks, pallets and during sorting. The system works as a supplement to other picking systems, such as Pick-by-Point®, Pick-to-Light or Voice Pickingetc. With Automotiv (always 1 item), the automatic confirmation of removal is triggered directly with the correct access. Goods issue is also a classic example of the use of the pick radar.

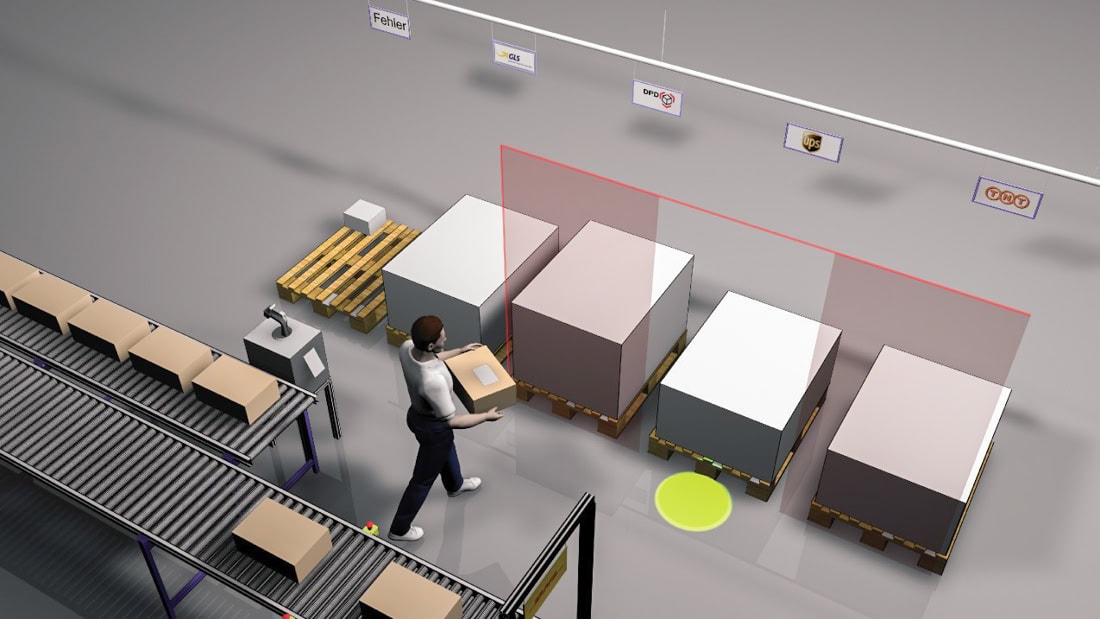

Example of parcel deposit control in an outgoing goods department

In this example, the Pick-Radar monitors the placement of the shipping carton on the correct pallet. The target pallet is specified here using a Pick-by-Point (the yellow light dot). If the carton is placed correctly, the system automatically acknowledges it. If the employee reaches into the wrong compartment, the light point of the Pick-by-Point turns red and large. Acoustic warning signals can also be used as an option. Sorting errors can be greatly reduced by using the Pick-Radar®.